Rotary Gear Pump

SPECIFICATIONS :

- Capacity : 400 LPM

- Pressure : Up To 10 KG/CM2

- Size : UP TO 3" inch

- Speed : 1450 rpm

- Temp. : Up to 80 C

WORKING :

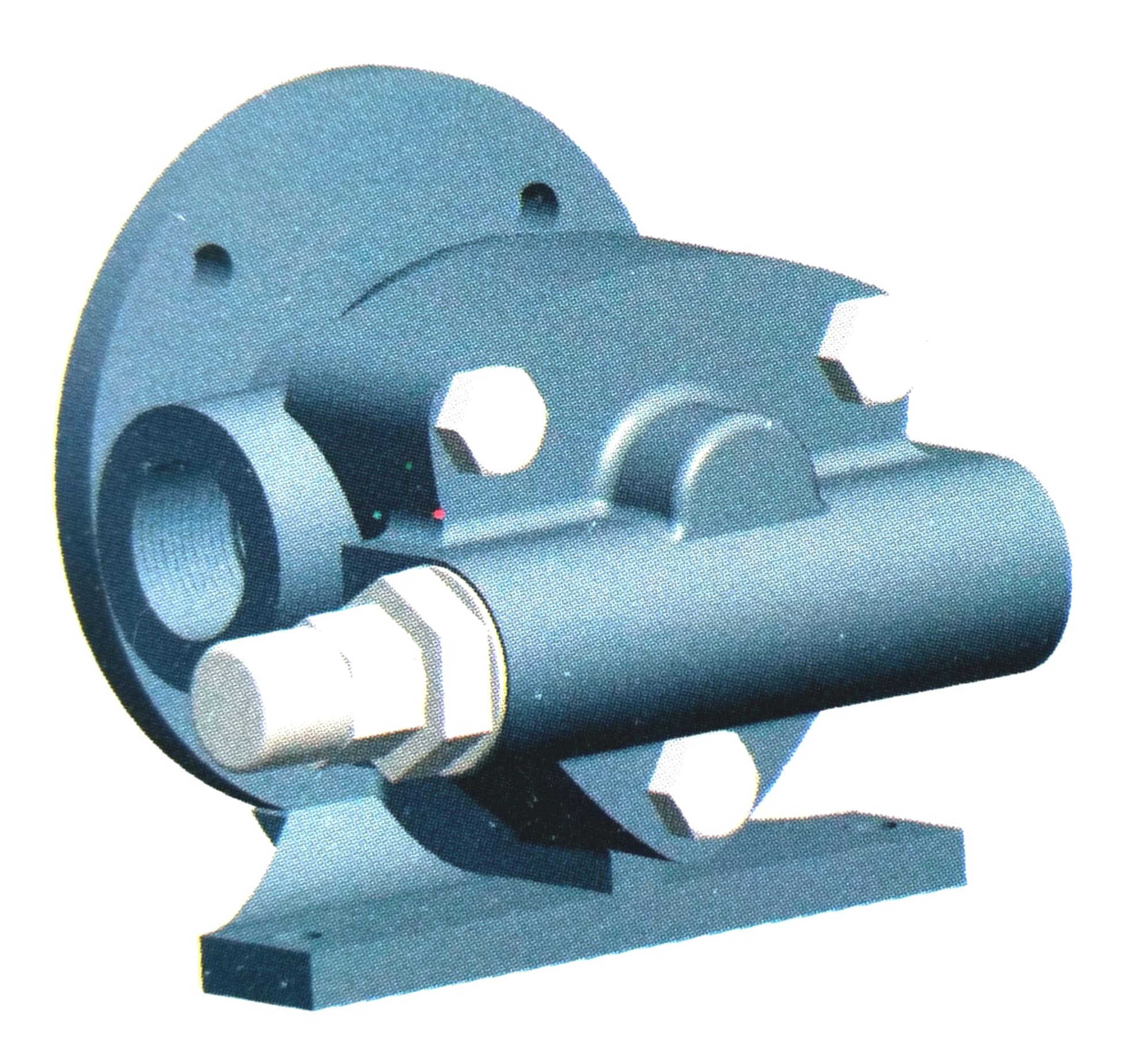

There are two Pumping Elements with Gear in Gear Principle.The rotors are mounted on single shaft well supported on both the ends.As the shaft rotates,they mesh & un-mesh displacing the liquid axially through Its pumping elements.Axial flow through elements ensures better suction capabilities,very low noise level and nearly pulsation free flow.These pumps have low power consumption compared too ther brands due to unique mounting of rotors.Rotors are produced using sintered metal technology and the other components are produced using the advanced manufacturing techniques with all the necessary quality checks for repeated accuracies in dimensions, guaranteed interchangeability and near to perfect pumping characteristics.This series is highly reliable when put to work on field,has longer service life,practically needs no maintenance and has reduced cost of the end product than the conventional equivalents to the customer.A standard pump would consists of Rotors in Sintered Iron,with built-in Relief Valve,Shaft in EN-8I ,SS-304,Lip Seal in Nitrile and all other contact parts in Cast Iron.

FEATURES :

Compact, Light Weight, Easy to Maintain and Ne at Design Can be Serviced in place without Disconnecting the Pipe lines & Motors (Applicable even for Mono Block Construction) Bi-Directional Integrated Shaft in Mono Block construction eliminating the shaft run out for the improved life of the lip seal. Also, Shaft is supported on 2X Bush Bearings as well as 2X Ball Bearings reducing the load on shaft as well as the pumps Pump Shaft Dynamtcally Balanced and Heat Dissipation is improved in Moria Block Design Engineered to run at High Speeds and adaptability of Mechanical Seals for Critical Application seven for lo'Aier flow rates Advanced Metallurgical Composition for Better & Longer Rotor Life Low Power Consumption & High Volumetric Efficiency.

APPLICATIONS :

Unloading and Transfer of Lubricating Oil from Tanks and Barrels Oil Circulation, Gearbox, Bearing and Pressure Lubrication Transfer of Fuel Oils from Daily Service Tanks,Pre Heaters and Filters Transfer and Circulation of Oil In Transformers & Oil Cleaning Machines Fuel Injection Pumps and as Booster Pumps in Oil Burner Services Unidirectional Flow Designs for Reversing Shaft Duties as in Machine Tools, Gear Boxes and Crane Duties In Hydraulic Power Packs Low Pressure-Continuous and Intermittent duty application.

MOC :

- CI ,EN-8 , SS-304 , SS-316 , SS-304L, SS-316L